Parker Hannifin Case Study

Dust Free PC has produced quality America-made NEMA-rated printer enclosures, computer enclosures, server enclosures, and more since 1999. With over 35,000 units deployed in multiple industries and environments, we have a solution to fit any need. That’s partly thanks to our specialty customizing unique enclosures to maximize the uptime of mission-critical systems.

Custom printer enclosures can benefit operations across a wide variety of industries. Read on for a case study on how one of our customers used them in a factory production environment.

Problem

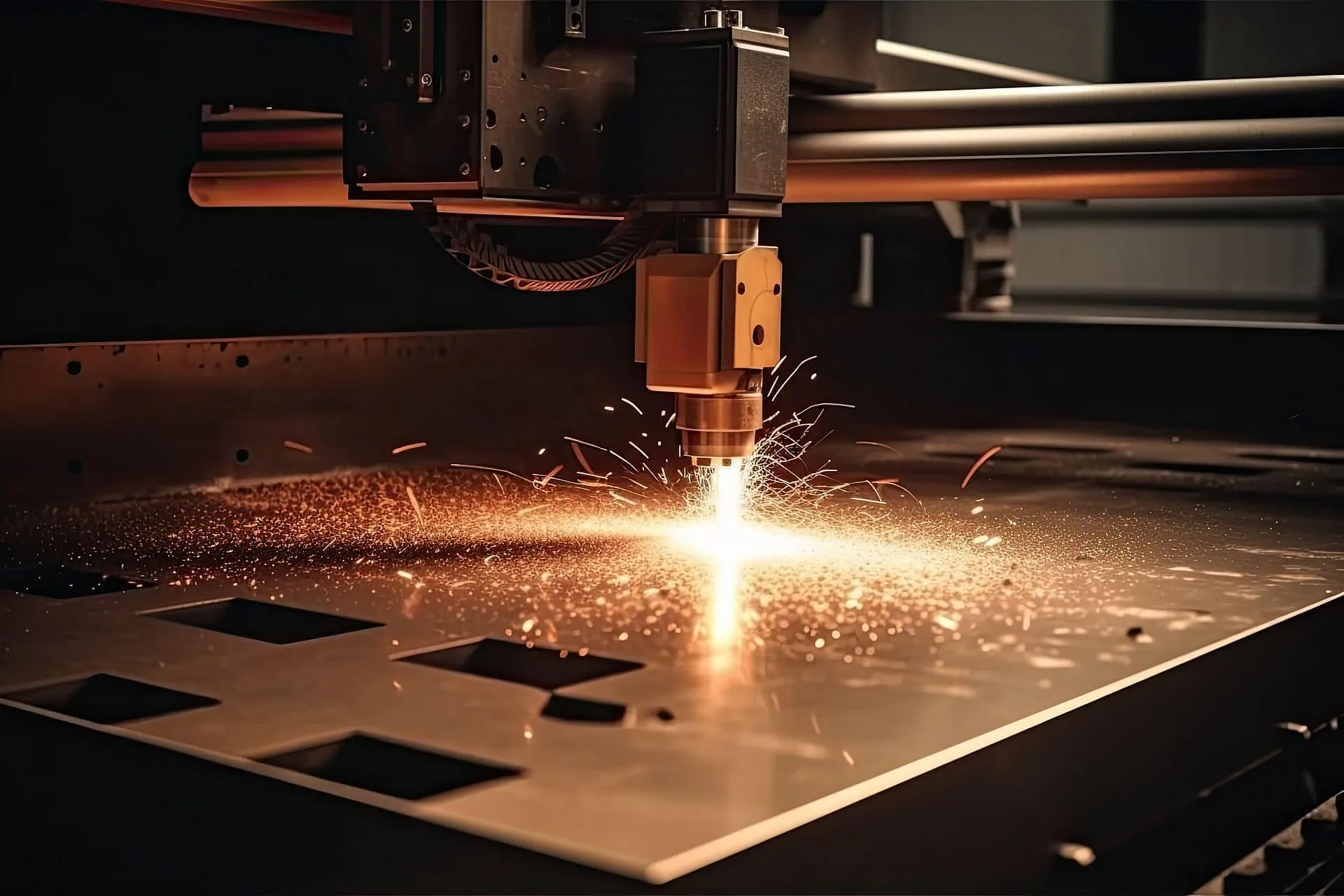

Parker Hannifin, a leading manufacturer of hydraulic pressure vessels, faced challenges in its operations due to outdated equipment for metal nameplate inscriptions. Their recent shift from manual typewriters to laser technology for metal nameplates brought efficiency but introduced new issues, such as fumes and particles interfering with the laser’s functionality.

“Most of our competitors have used laser etching for a long time,” said Parker Hannifin’s Engineering Specialist, Jim Robertson. “Making the switch saved us lots of time and money, but the dust and fumes were issues we needed to address.” Additionally, the company struggled with maintaining optimal conditions for thermal printers in their paint line, resulting in printer failures during winter months and wasted labels.

Strategy

Dust Free PC’s strategy involved creating a controlled environment for laser engraving and protecting thermal printers from the effects of cold air. Our team set out to develop and produce customized enclosures tailored to Parker Hannifin’s specific needs.

For the laser engraving process, an enclosure was designed to prevent fumes and particles from affecting the laser’s performance. For the thermal printers in the paint line, our team collaborated to develop an enclosure with a plexiglass door to shield printers from cold air, enhancing overall efficiency.

Dust Free PC successfully created and delivered Parker Hannifin’s enclosures in under two weeks, exceeding customer expectations. “Jason looked at my specs, and we explored ideas for shelving and doors that I was not aware we could implement,” said Robertson. “I was able to send him my ideas for both enclosures, and he successfully honed in on what we wanted.”

Outcome

Upon completion, Dust Free PC’s laser enclosure facilitated precise metal nameplate inscriptions, saving time and money and creating a more professional look. The thermal printer enclosure was designed to maintain constant temperature and protect against cold air, which resulted in improved printer performance, reduced label wastage, and enhanced operational efficiency.

“I’m extremely pleased with the products and, most of all, the quick turnaround,” said Robertson. “Jason is easy to work with and get a hold of. He’s always been right there to answer all my questions.” The customization services provided allowed for adjustments to dimensions, doors, and shelving, ensuring the final product met all of the customer’s specific needs.

“The pricing was phenomenal,” added Robertson. “I recommend Dust Free PC to others all the time. They have helped our team members work more efficiently – you can truly tell them what you need and they make it happen.”

Need Custom Printer Enclosures? Contact Dust Free PC.

Dust Free PC is a premier NEMA-rated computer enclosure/cabinet manufacturer for industrial markets worldwide. If your company needs a custom enclosure solution, our team is ready to help. Call our team at 904-739-7201 or email Sales@dustfreepc.com.